Long-life passive room tempered vacuum glass

Abstract : How many years can the energy saving effect last after passive house acceptance? The life of the window glass has a huge impact on it. The tempered vacuum glass has excellent thermal insulation performance, and also completely solves the problems of air-sealing rubber leakage and oxidative failure of LOW-E film which plague the four-glass three-chamber insulating glass. Increased strength and complete thinness make installation and use easier. The intimate design of the “vacuum eye” in the tempered vacuum glass allows the user to know the life of the window at any time, making the passive room window a true product.

Keywords: passive house; steel vacuum glass; windows; life

Introduction

Passive house construction has been widely promoted around the world since its introduction in 1988. Low energy consumption is achieved by high-insulation, building facades, doors and windows. The natural lighting of comfortable buildings is inseparable from glass. At present, four glass three-chamber insulating glass or ordinary vacuum glass with poor light transmittance is used in the house, but a large amount of glass has leaked but has not attracted enough attention. How do users know if their window glass has leaked? How to make the life of the window glass reach the long life of the passive room? We have done some useful explorations in tempered vacuum glass.

Table 1 Comparison of service life of three types of glass

| Tempered vacuum glass | Ordinary vacuum glass | Four glass three-chamber insulating glass | ||

| Insulation life display | Yes | No | No | |

| Edge life | Long | Long | Short | |

| LOW-E film life | Long | Long | Short | |

| Service life | Strength | Good | difference | in |

| Thin and light | Good | in | difference | |

1, the user needs to know the insulation life of the window glass at any time.

The current windows are getting more and more expensive. Whether the glass as the main material of the window is still energy-saving during use, there is no simple and feasible evaluation method for users and manufacturers. It is impossible for everyone to use expensive and complicated professional testing instruments to monitor every piece of glass every day. This leads to a large number of inferior products flooding the market, and the social energy consumption is high, and users can have problems.

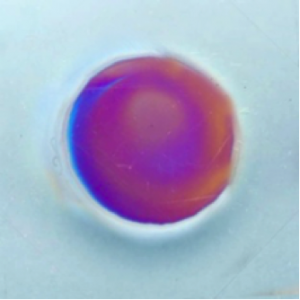

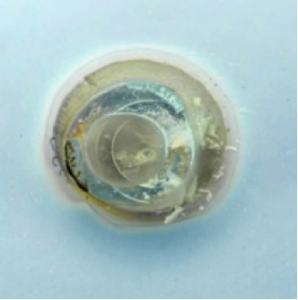

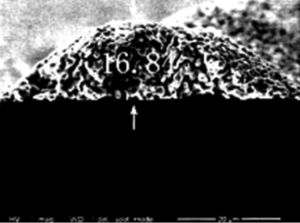

Fifteen years ago, we conquered this worldwide problem: in the field of view of tempered vacuum glass, the “vacuum eye” of this fingernail size was successfully set. When the internal vacuum is constant, the vacuum eye remains unchanged. When the degree of vacuum drops, the vacuum eye becomes small. When the vacuum disappears, the vacuum eye disappears. The disappearance of the vacuum eye indicates that the glass leaks, indicating that the conduction and convection in the glass are greatly increased; it also indicates that the LOW-E film will soon be oxidized and the radiation heat transfer will be greatly increased; that is, the glass shelf life should be Free replacement.

|

|

So what causes the failure of various glasses? The following will elaborate on three aspects:

- Comparison of edge sealing life of several materials

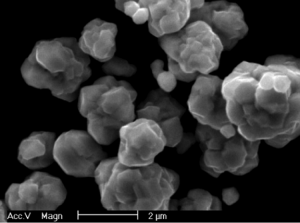

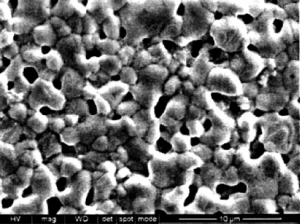

2.1 Inorganic low melting point glass edge sealing performance

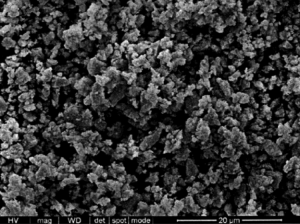

Low-melting glass originated from Chinese ancient glaze more than 2,000 years ago and is the oldest glass variety in the world. Low-melting glass is commonly used in vacuum sealing between glass, metal and ceramics in electronic devices, and has wide applications in household appliances, vehicles, aerospace and other fields. Since Tang Jianzheng produced the world’s first vacuum glass sample at the University of Sydney more than 20 years ago, low melting glass is the only time-proven qualified vacuum glass edge banding material. The low-melting glass melts and infiltrates with the flat glass to form a chemical bond between the atoms, and after cooling, becomes a dense whole with the glass plate. Its air tightness, strength, weather resistance, and service life are comparable to those of glass panels, and can withstand harsh weather conditions. Vacuum glass life can reach up to 50 years (image 3)

|

In 1995, we developed a low-melting glass with a sealing temperature of 430 ° C for the sealing of vacuum glass. However, when we tried to produce tempered vacuum glass, we found that the tempered glass was annealed into ordinary glass at a high temperature of 430 °C.

Through unremitting efforts, in 2001, we successfully produced tempered vacuum glass by using infrared local heating method, and the state of debris during testing reached the national standard for tempered glass [2] Successfully applied for a US patent and a large number of Chinese patents.

The infrared local heating method has low production efficiency, complicated process and low yield, which prompts us to further develop lower melting point sealing glass. A lead-free low-melting glass sealed at a temperature of 360 ° C and a lead-containing low-melting glass at 300 ° C were successively introduced. These low-melting glass materials are suitable for various tempered vacuum glass manufacturing processes, meeting the requirements of production efficiency and yield.

|

In 2003, a pilot test line was successfully built. In 2007, Pingfengkou Tempered Vacuum Glass Technology won the second prize of China Building Materials Science and Technology.

|

Henan Longwang Steel Vacuum Glass Co., Ltd. was founded at the end of 2013 and mass production in 2015. The single-piece tempered vacuum glass product passed the test of the China Building Materials Science Research Institute in 2015 and completely met the requirements of the passive house.

|

2.2 Low melting point alloy edge sealing performance

Vacuum sealing of glass and metal is also a mature technology. In the finished product, glass and metal penetrate each other at the interface to form a firm and dense vacuum sealing layer, but it is often used in small electronic devices.

|

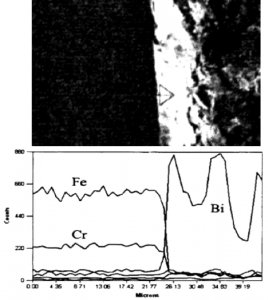

Large-size glass-to-metal connections are commonly found in the firing of conductive silver paste on automotive backstops. We have also tried to seal the vacuum glass by means of a low melting point alloy having a melting point of less than 350 ° C. It has been found that the low melting point alloy does not currently meet the sealing and strength requirements.

In the process of glass tempering, the silver paste is firmly adhered to the surface of the glass plate by the low-melting glass powder in the silver paste. While the low-melting glass melts during the tempering process, the glass melt fully wets the glass by capillary action. The surface of the board is wrapped with silver powder to hold the silver powder on the surface of the glass sheet. The silver powder melts and interconnects in the glass melt and re-solidifies with the tempering cooling process to form a non-dense silver layer. When the content of the low-melting glass frit is small, the silver powder is difficult to be sintered on the glass plate. When the glass powder content is high, the adhesion between the silver layer and the glass plate is good, but the glass powder floats on the surface of the silver layer during the tempering, and the silver layer and the low melting point alloy are difficult to weld. However, no matter how it is adjusted, the formed silver layer is not dense enough, and there is a gas leakage passage. Although it can meet the electrical conductivity requirements of the rear end of the automobile after welding with the low melting point alloy, it cannot meet the vacuum sealing requirements of the vacuum glass. Even if vacuum is occasionally obtained on small-sized products, it is difficult to meet the harsh manufacturing, transportation, installation, and use requirements of glass because sufficient welding strength is not obtained.

|

|

|

2.3 Organic rubber edge sealing performance

In the current production of insulating glass, organic rubber edge sealing is commonly used. The gas permeability of the organic gum used is shown in the following table:

Table 2 Gas permeability of insulating glass edge banding glue

| Sealant variety | Argon permeability g/m 2 d | Water vapor permeability g/m 2 d |

| Butyl rubber | (5~8)×10 -3 | — |

| Polyurethane glue | (5~8)×10 -3 | 1~4 |

| Polysulfide | (5~8)×10 -3 | 7~9 |

| Silicone glue | (500~1000)×10 -3 | 15~20 |

Table 3 Argon leakage rate of insulating glass [3]

| Insulating glass variety | Argon leakage rate under atmospheric cycling test conditions | Argon leakage rate under high humidity test conditions |

| Double-sealed insulating glass with silicone glue | 2.38% | 18.07% |

| Composite aluminum foil rubber strip (comfort strip) single-pass sealed insulating glass | 33.66% | 0.90% |

| Insulating glass of double-channel sealing structure of silicone microporous spacer strip (super spacer strip) | 0.93% | 1.07% |

According to the law of partial pressure, the current argon-filled four-glass three-chamber insulating glass, the rate of argon gas permeating through the two-way sealant is 2.4 times faster than the penetration of outside air into the hollow glass, so the trend of leakage It is inevitable. This defect of the organic glue causes the argon gas in the hollow glass to gradually decrease, the internal pressure of the glass to decrease, the surface of the glass to bend inward, and the stress on the edge of the glass to occur, and the opening and bursting often occur. Some manufacturers in the world promise to guarantee the life of sealant for 25 years, but from the practical point of view, most of the hollow glass windows have been filled with water within less than ten years, and the glass has failed.

At the beginning of the development of vacuum glass, we also tried to seal with organic glue, and found that the current organic glue cannot meet the requirements.

3, LOW-E film life comparison in three kinds of glass

At present, the best energy-saving effect is off-line three-silver LOW-E coated glass, and off-line double-silver LOW-E coated glass is also used more, but these two silver films are easily oxidized, so they are often used for tempered vacuum glass or argon-filled gas. Insulating glass. As long as the “vacuum eye” exists in the tempered vacuum glass, it indicates that the internal vacuum perfectly protects the off-line LOW-E coated glass. However, due to air leakage, it is difficult for the insulating glass to protect the off-line LOW-E coated glass from oxidation.

In addition, in the vacuum box method and the gas replacement method used for filling the argon gas of the four-glass three-chamber hollow glass, the air replacement method, which is inferior in the domestic use is commonly used. No matter which one is used, there is a case where the argon gas is insufficient. The national standard requires that the level of argon gas filled by the manufacturer reaches 90%, but a large number of sampling results show that the argon gas in a large number of hollow glass is only 50%, plus the leakage of organic glue, the argon in the hollow glass of the user during use. The gas content is even lower. Under such conditions, the oxygen in the four-glass three-chamber hollow glass has already oxidized the LOW-E.

- Comparison of service life of three kinds of glass

4.1 Influence of strength on life

The maximum principal stress of the glass in a monolithic glazing is concentrated at the corners of the edge of the glass, which reduces its wind pressure resistance. The maximum principal stress of the insulating glass is in a non-uniform decreasing form. Both have no uniform stress distribution of vacuum glass

The tempered vacuum glass presses two pieces of glass tightly together due to atmospheric pressure to form a whole, and the wind pressure resistance is nearly twice that of the four glass three-chamber insulating glass. The ordinary vacuum glass we made fifteen years ago is much lower in strength due to the non-tempered glass. In addition, the spherical support used at that time forms a Brinell hardness indenter effect on the glass surface, and the inner surface of the ordinary vacuum glass is pressed out. The pits, stress concentration and micro-cracks that are difficult to see by visual observation when the user suddenly ruptured the vacuum glass at the support part during use, which affected the market promotion.

At present, the introduction of tempered vacuum glass has completely solved this problem. And because it has experienced high temperature hot dip at around 300 °C during its production process, the risk of self-exposure of tempered glass is much lower than that of four-glass three-chamber insulating glass, and its life expectancy is better.

4.2 The impact of thinness on life

The window is laborious and dangerous during the installation process. Whether it is to install the glass after the window frame is installed at the construction site, or to make the finished window at the window factory to the construction site for one-time installation, the design and on-site construction personnel hope to adopt thin and light products. This is not only conducive to on-site construction, but also beneficial to the strength of the wall structure of the passive house, the setting of the insulation layer and the maintenance of the window. These are good for the life of the passive house.

However, the four-glass three-chamber hollow glass is thick and heavy. In order to accommodate it, the window frame has to be made thick and heavy, and the hardware and other materials are correspondingly thickened. In order to meet the national safety requirements, ordinary vacuum glass that we used to do has to be combined with the third and fourth pieces of tempered glass into hollow glass or laminated glass. Although it is a little thinner than the four-glass three-chamber insulating glass, the weight is increased. The thin and light advantages of vacuum glass are not fully utilized.

The introduction of tempered vacuum glass makes vacuum glass no need to recombine hollow or laminating, which achieves lightness and thinness while meeting safety requirements, completely liberating the designers and construction personnel of passive houses, and saving energy and materials. No matter whether it is the south house or the north house of the passive house, it can provide users with large windows, large view and large lighting. The value of the developer’s home has been improved.

5 Conclusion

The tempered vacuum glass is completely sealed by the low-melting glass edge, which completely solves the problem of leakage of the edge-sealing rubber which plagues the four-glass three-chamber insulating glass. At the same time, it solves the problem of rapid oxidation failure of the LOW-E film in the four-glass three-chamber insulating glass; The realization of lifting and thorough thinning makes the life of the passive room window greatly improved, and the glass life can reach more than 50 years. The intimate design of the “vacuum eye” in tempered vacuum glass allows users to know the life of their windows at any time. Users can understand and use it with confidence. Tempered vacuum glass makes passive room windows a true conscience product.

References:

[1] Xu Wei, Tang Jianzheng. Why does passive house choose vacuum glass? [J]. Construction Technology, 2014, 19: 74-76.

[2] Li Hongyan, Wu Jusheng. Double-sided tempered vacuum glass and Manufacturing method [P]. 03160042.5, 2003-9-23.

[3] Gao Shulan, Yan Shuwei, Wang Tiehua. Analysis of the Causes and Solutions of Inert Gas Leakage in Insulating Glass[J]. , 2008, 207(12): 35- 39.

. [4] Zouhui Fen, Wang Xuefeng, Sun Yang, Li comet, Xu Tiejun stress at the glass vacuum glass column support analysis [J] Shenyang Jianzhu University Natural Science, 2010, 26 (2): 355-359.

[ 5] Liu Xiaogen, Bao Yiwang, Wan Detian, Li Kunming, Xu Haifeng, Lu Jia. Basic theoretical analysis of vacuum glass structure optimization design [J]. Doors and Windows, 2009, 5: 38- 42.