The most commonly used traditional doors and windows are ordinary UPVC and aluminum alloy doors and windows. Aluminum alloy doors and windows have the advantages of high strength, good ductility, and high heat transfer coefficient, while UPVC doors and windows have low strength, poor ductility, and low heat transfer coefficient.

Later on, thermal bridge aluminum alloy doors and windows combine the two characteristics, adding nylon partitions in the middle of the aluminum alloy, significantly reducing the aluminum alloy. The heat transfer coefficient of alloy doors and windows enhances the thermal insulation performance of doors and windows.

The K value of aluminum with thermal break is around 2.4-2.8, which is still far insufficient for the standard of the passive houses. Instead, our innovative FRPU frames can solve this problem.

Fiberglass-reinforced polyurethane (FRPU) is a high-performance composite material. Its high strength, low thermal conductivity, and corrosion resistance make it used in aviation aircraft, wind turbine blades, and seaside flood control fields.

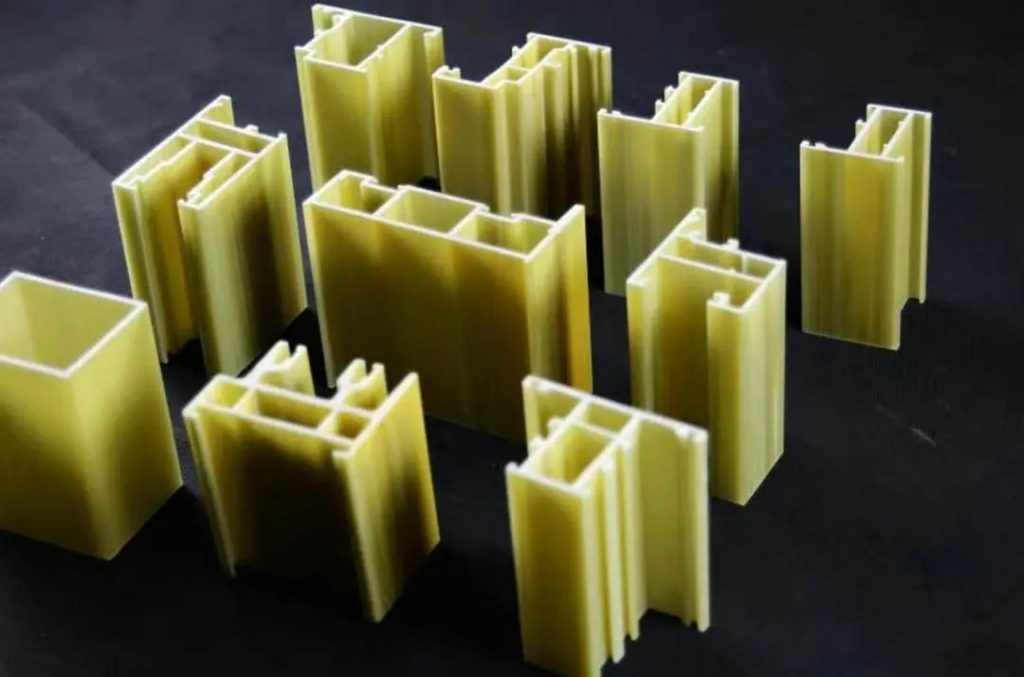

Our FRPU profile is produced by the pultrusion process. The continuous glass fiber roving is immersed in the mixed polyurethane glue and heated and cured under the traction force of the pultrusion molding unit to form a new type of door and window profile. Glass fiber polyurethane energy-saving doors and windows are energy-saving door and window products made of polyurethane profiles as the main force-bearing components of door and window frames, using systematic window assembly technology, assembling door and window frames with hardware accessories, and then configuring insulating glass.

Polyurethane profiles have good impact resistance, convenient cutting, and smooth cuts. The performance of doors and windows has been optimized. Under the premise of ensuring strength, the profile has a small weight.

The main performance parameters of glass fiber polyurethane profiles are shown in the table below:

Performance parameters of glass fiber polyurethane profiles

Project indicators

| Longitudinal bending strength: | >1 000 MPa |

| Transverse bending strength | MPa >50 |

| Longitudinal flexural modulus | M40 GPd |

| Pendulum impact strength along the fiber direction | 10 M |

| Resin content | 18-33 |

| Resin insoluble content | 385 |

| Barcol hardness, | >40 |

| Thermal conductivity | 0.25W(m・K) |

It can be seen from the table that fiberglass polyurethane profiles have excellent mechanical properties, high bending strength, and elastic modulus, which determines the role of glass fiber polyurethane profiles in doors, windows, curtain walls, skylights, partitions, canopies, ceilings, etc. Advantage application.