Our toughened vacuum glass products are branded VacuGlaze™.

It separates the two pieces of glass with a 0.4 mm support and seals the edges of the two glass sheets with low melting point glass to separate the vacuum from the air. The vacuum space between the glass has an extra-low atmospheric pressure of 0.0001 Pa. As for the high vacuum degree, the heat convection no longer exists, the heat conduction is reduced to next to zero, and the LOW-E layer reflects more than 95% of the infrared radiation, so the heat between the inner and outer glass panels cannot be exchanged so that to achieve excellent thermal insulation.

Toughened vacuum glass size: up to 3000x2000mm; minimum 200x200mm; thickness 8.4~35.16mm.

| Glass type | Total thickness (mm) | Heat transfer coefficient (K value: W/m2·K) | Visible light transmittance (%) |

Shading coefficiency (SC) value |

|

VacuGlaze™ for Conservatories |

12.4mm | 0.4W/m2 | 49% |

0.34 |

|

VacuGlaze™ for Passive Houses |

12.4mm | 0.6W/m2 | 72% |

0.62 |

|

VacuGlaze™ composited with double glazing |

29.4mm | 0.38W/m2 | 44% |

0.31 |

|

Laminated VacuGlaze™ composited with double glazing |

35.16mm | 0.38W/m2 | 44% |

0.31 |

VacuGlaze is the world’s most cost-effective window glass product.

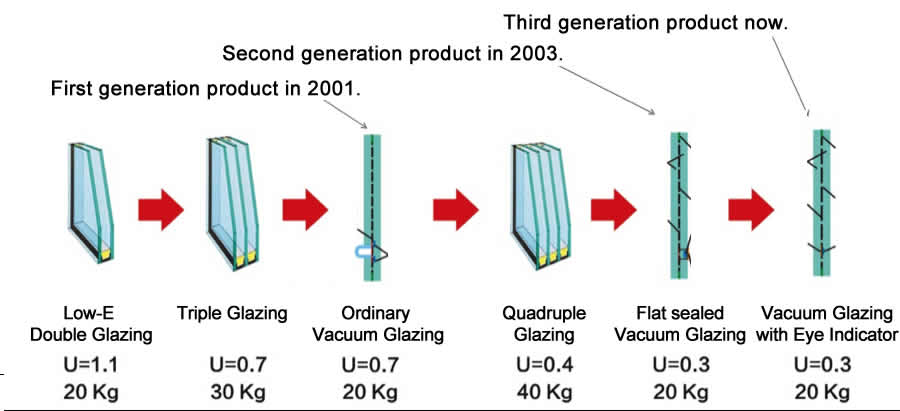

Triple glazing two-chamber glass contains three pieces of LOW-E glass. Both chambers are filled with argon and are sealed with highly insulated edge strips. The central heat transfer coefficiency K value can only reach 0.7W/M2 at its best.

We use tempered vacuum glass made of two pieces of LOW-E glass. The central heat transfer coefficient has reached 0.23W/M2, three times as warm as triple-glazing.

VacuGlaze has a life span of 50 years. The maximum life of triple glazing on the market is only about 25 years, meaning the service life is twice that of triple glazing.

Technical characteristics of VacuGlaze:

Wind pressure resistance

Wind pressure resistance

Less than half the thickness of double glazing, twice the strength of wind pressure resistance of double glazing.VacuGlaze is a material that connects two pieces of toughened glass and titanium alloy under atmospheric pressure. It has high resistance to deformation under the action of external force. VacuGlaze improves its wind pressure resistance and strength, which is more resistant to wind pressure than ordinary double or triple glazings.

Sun protection, heat resistance

Sun protection, heat resistance

- The nano-silver film reduces indoor temperature significantly and blocks ultraviolet rays to keep family members away from air-conditioning diseases and protect eyesight and skin. VacuGlaze was installed in a test room with an extra high temperature of 100°C for 385 days of continuous testing. The tempered vacuum glass was not damaged, and the deformation was only 1%. The high thermal insulation performance remained unchanged. This shows that VacuGlaze can be used safely in different harsh environments in various places.

Ultra acoustic insulation

Ultra acoustic insulation- The acoustic insulation ability of VacuGlaze is 11 decibels higher than that of ordinary insulating glass. The acoustic insulation of a single piece can be as high as 41 decibels. According to the different needs of users, we can compound with double glazing or laminated glass to make a better acoustic insulation performance. VacuGlaze keeps you away from noise hazards.

Anti-condensation

Anti-condensation- VacuGlaze has good anti-condensation performance, and its condensation temperature is below minus 50°C. With its good heat insulation ability, the central condensation temperature of tempered vacuum glass drops below -50°C. The light transmittance of the product will not be affected by condensation in winter.

Suitable for various installation angles and altitudes

Suitable for various installation angles and altitudes- When the installation angle of a double glazing frame is 30 degrees, its thermal insulation effect is reduced by 45%; when the installation angle is 60 degrees, its thermal insulation effect is reduced by 30% (the reason is: when the installation angle becomes smaller, the gas convection from the hot side to the cold side distance becomes shorter, resulting in faster heat loss). Whether VacuGlaze is installed on the skylight of the roof or any other position, its thermal insulation performance will not decrease with the change of the installation angle.

Ultra-thin, non-deformable, and easy to open and close

Ultra-thin, non-deformable, and easy to open and close- The 12.4mm VacuGlaze is much thinner than the 20-50mm double/triple/quadruple glazing and has lower requirements for structural frame materials and hardware components. It will reduce the materials of doors, windows, and curtain walls by about 50%. The window is difficult to sag and deform and has a longer service life. It will be easier to open by the elderly and children.